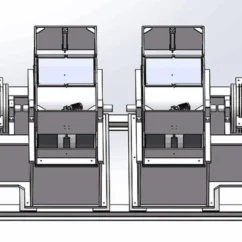

Automobile Tire Testing Equipment

In the modern automotive industry, 3D laser four-wheel aligners play a crucial role. As automotive technology continues to advance and the design and manufacture of vehicles become more complex, ensuring the safety and performance of vehicles has become a top priority for car manufacturers and service providers. As a high-precision measurement tool, the 3D laser four-wheel locator can help professional technicians accurately adjust the vehicle’s tires and suspension system to ensure the stability and safety of the vehicle during driving. First of all, the 3D laser four-wheel locator can provide extremely high measurement accuracy. Compared to traditional mechanical or optical locators, 3D laser technology can capture more subtle changes in Angle and distance. This high precision measurement capability allows the technician to make more precise adjustments to the four wheels of the vehicle, thereby improving the handling performance and driving comfort of the vehicle. Secondly, the 3D laser four-wheel locator also has significant advantages in improving work efficiency. The traditional four-wheel positioning process usually takes a long time and requires a high level of experience for the technician. The 3D laser four-wheel locator greatly reduces positioning time and dependence on technician experience through automated measurement and analysis functions. This not only improves the efficiency of maintenance services, but also reduces the possibility of human error. In addition, the 3D laser four-wheel locator also performs well in data management and analysis. Modern 3D laser four-wheel positioning systems are often equipped with advanced software that can record and analyze large amounts of measurement data. This data can be used not only for current vehicle adjustments, but also for future repairs and maintenance. This data-driven approach helps to improve the overall level of vehicle maintenance and extend the service life of the vehicle. In short, the importance of 3D laser four-wheel locator in the automotive industry cannot be ignored. It not only improves the safety and performance of vehicles, but also improves the efficiency and quality of maintenance services to a large extent. With the continuous advancement of technology, 3D laser four-wheel locator will continue to play a key role in the automotive industry, escorting the safe driving of vehicles.

Free shipping on orders over $50!

- Satisfaction Guaranteed

- No Hassle Refunds

- Secure Payments

The non-contact four-wheel positioning instrument is a special device used to measure and adjust the wheel positioning of the assembled vehicle. Through the positioning instrument, the four-wheel positioning of the vehicle is located and measured/judged to ensure that the wheel positioning meets the design parameters and requirements.

Wheel weight, toe in and camber of wheels, inspection of main pin camber, camber, thrust angle, and maximum steering angle, calibration of toe in and camber, automatic collection and calibration of wrench torque to a specified database, and optional wheel arch inspection function.

Innovative advantages: Exclusive invention patents leading the world, side cameras added to the front wheels and targets added to the rear wheels, automatic calibration of the zero point value of the rear wheel sensors after changing the wheelbase, eliminating initial errors and ensuring accurate measurement results.

Exclusive innovative wheelbase adjustment mechanism ensures that the wheel rotation center coincides with the drum group rotation center, accurately measuring the maximum steering angle.

Test content:

Front wheel front bundle (left/right), front wheel total front bundle, rear wheel front bundle, front wheel out (left/right), kingpin back tilt, kingpin inward tilt, rear wheel out (left/right), maximum steering Angle, etc. The device can be measured repeatedly by static/dynamic measurement and adjustment, the front bundle and roll out of the wheel, the display in the control cabinet, the display above the front of the car and the operator’s display in the pit to display the measurement value in real time.

Kingpin back tilt Angle, kingpin inner tilt Angle measurement method: random inspection.

Measuring range (accuracy calibrated with static calibration stand):

| Item | Test range | Precision | Repeat accuracy | Remark |

| Front pulley | ±10° | ±1′ | ±0.2′ | 100% detection |

| Wheel roll out | ±10° | ±2′ | ±0.4′ | 100% detection |

| Thrust Angle | ±10° | ±2′ | – | 100% detection |

| Steering wheel Angle | ±10° | ±0.5′ | ±0.5° | 100% detection |

| Kingpin tilted inward | measuring range±20° | – | <±4° | 100% detection |

| Kingpin leans back | measuring range±20° | – | ±0.1° | 100% detection |

| Maximum steering Angle | ±45° | ±0.1° | ±0.1° |

The non-contact dynamic four-wheel positioning instrument adopts the non-contact German visicon laser measurement system and the imaging processing technology of line laser irradiation, which has the characteristics of high measurement accuracy, small repeatability error and stable operation.

Hot Tags: automobile tire testing equipment, China automobile tire testing equipment manufacturers, suppliers, factory, Car Chassis Dynamometer, ADAS, Veneer Side Slip Tester, Vehicle Rain Test Room, Semi automatic Headlight Tester, Multi function Roller Test Stand

Reviews

There are no reviews yet.