Non-contact Laser Locator

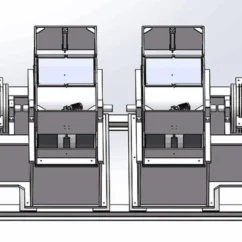

The non-contact four-wheel locator is an advanced automotive diagnostic device that uses laser and sensor technology to measure four-wheel positioning data without contact with the car tire or steel rim. Its main components include model and function selection device, ground operation display, 3D laser CCD sensor assembly, pit display device, pit lighting and ventilation device, vehicle centering device, vehicle positioning device, wheelbase adjustment device, driving guidance device, PLC electrical control cabinet, steering wheel positioning device, computer hardware and software system, etc . Compared with the traditional four-wheel locator, this device has higher measurement efficiency and lower failure rate, while avoiding damage to the rim in the measurement process, reducing the work intensity and improving the measurement accuracy . The launch of the non-contact four-wheel positioning instrument marks the further development of automotive diagnostic technology and indicates the change of the future automotive maintenance industry .

Free shipping on orders over $50!

- Satisfaction Guaranteed

- No Hassle Refunds

- Secure Payments

The non-contact four-wheel positioning instrument is a special device used to measure and adjust the wheel positioning of the assembled vehicle. Through the positioning instrument, the four-wheel positioning of the vehicle is located and measured/judged to ensure that the wheel positioning meets the design parameters and requirements.

Wheel weight, toe in and camber of wheels, inspection of main pin camber, camber, thrust angle, and maximum steering angle, calibration of toe in and camber, automatic collection and calibration of wrench torque to a specified database, and optional wheel arch inspection function.

Innovative advantages: Exclusive invention patents leading the world, side cameras added to the front wheels and targets added to the rear wheels, automatic calibration of the zero point value of the rear wheel sensors after changing the wheelbase, eliminating initial errors and ensuring accurate measurement results.

Exclusive innovative wheelbase adjustment mechanism ensures that the wheel rotation center coincides with the drum group rotation center, accurately measuring the maximum steering angle.

Test content:

Front wheel front bundle (left/right), front wheel total front bundle, rear wheel front bundle, front wheel out (left/right), kingpin back tilt, kingpin inward tilt, rear wheel out (left/right), maximum steering Angle, etc. The device can be measured repeatedly by static/dynamic measurement and adjustment, the front bundle and roll out of the wheel, the display in the control cabinet, the display above the front of the car and the operator’s display in the pit to display the measurement value in real time.

Kingpin back tilt Angle, kingpin inner tilt Angle measurement method: random inspection.

Measuring range (accuracy calibrated with static calibration stand):

| Item | Test range | Precision | Repeat accuracy | Remark |

| Front pulley | ±10° | ±1′ | ±0.2′ | 100% detection |

| Wheel roll out | ±10° | ±2′ | ±0.4′ | 100% detection |

| Thrust Angle | ±10° | ±2′ | – | 100% detection |

| Steering wheel Angle | ±10° | ±0.5′ | ±0.5° | 100% detection |

| Kingpin tilted inward | measuring range±20° | – | <±4° | 100% detection |

| Kingpin leans back | measuring range±20° | – | ±0.1° | 100% detection |

| Maximum steering Angle | ±45° | ±0.1° | ±0.1° |

The non-contact dynamic four-wheel positioning instrument adopts the non-contact German visicon laser measurement system and the imaging processing technology of line laser irradiation, which has the characteristics of high measurement accuracy, small repeatability error and stable operation.

The proper axial position of a vehicle’s tires is essential for ensuring safe and smooth driving. To achieve this, our company has developed advanced equipment for detecting the axial position of tires, which boasts outstanding technical features and stable performance.

This equipment is based on high-precision sensors and cutting-edge image recognition technology that can swiftly and accurately detect the wheel’s position. The sensors are placed at the center of the wheel hub, and as the wheel rotates, they collect data on its position. Additionally, the image recognition system analyzes the tire rotation to determine the tire’s displacement.

One of the significant advantages of this equipment is its accuracy. It can determine the axial position of the tire within a range of 0.01 mm, ensuring that each tire is precisely aligned. This accuracy is essential because any misalignment can cause uneven tire wear and negatively impact the vehicle’s performance and safety.

Moreover, our equipment is incredibly versatile and can be used to test vehicles of different sizes, ranging from small passenger cars to large commercial trucks. With our device, accuracy, and speed, we can determine the axial position of each vehicle’s tires within a matter of minutes.

In summary, the advanced equipment we have developed for detecting a vehicle’s tire position is an essential tool for ensuring safe and smooth driving. Its technical features, high accuracy, and speed make it highly reliable and efficient. Choosing our equipment means choosing the best for your vehicle.

Hot Tags: non-contact laser locator, China non-contact laser locator manufacturers, suppliers, factory, Steering Wheel Stand, High end Inspection Line, Vehicle Inspection Line, Vehicle Sideslip Test Bench, Head up Display HUD , Off line Detection Line

Reviews

There are no reviews yet.